Natural rubber at a glance

A unique material offering unparalled properties such as elasticity, permeability, mechanical resistance, and electrical insulation.

What is Natural Rubber?

Natural rubber, the tears of a tree - Rubber is harvested by slicing the bark of the rubber tree. The term rubber comes from the indigenous Amazonian words "kau" and "chuk", which together mean "weeping wood".

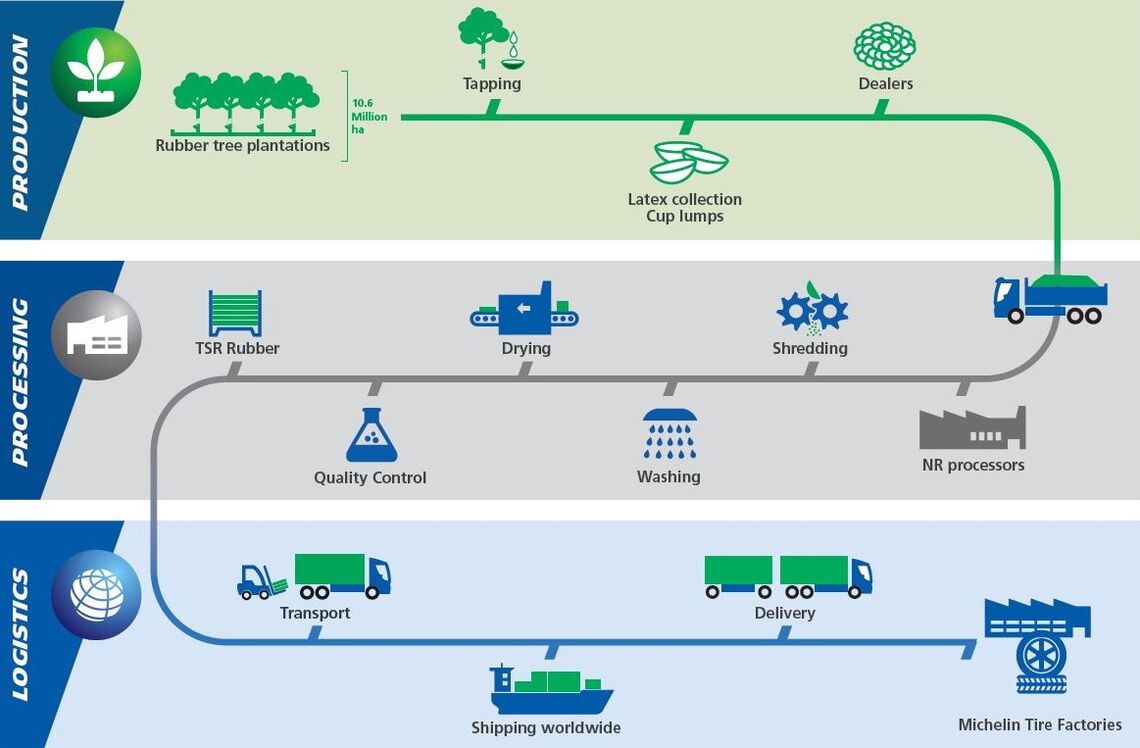

Natural rubber value chain

Michelin supports a responsible and resilient management of the natural rubber value chain.

It is essential that rubber is produced in a responsible manner to contribute to the sustainable mobility of tomorrow.

The five main groups of stakeholders involved in the value chain are:

Cultivating, harvesting and processing natural rubber provides stakeholders in the supply chain with regular and sustainable revenue while contributing to the development of rural areas.